In the world of construction, selecting the right formwork system is crucial for the success of any project. LVL (Laminated Veneer Lumber) formwork is quickly becoming a preferred choice among builders and contractors. This article will delve into the various aspects of LVL formwork, highlighting its benefits and explaining why it’s the optimal option for your construction needs.

Understanding the Basics of LVL Formwork

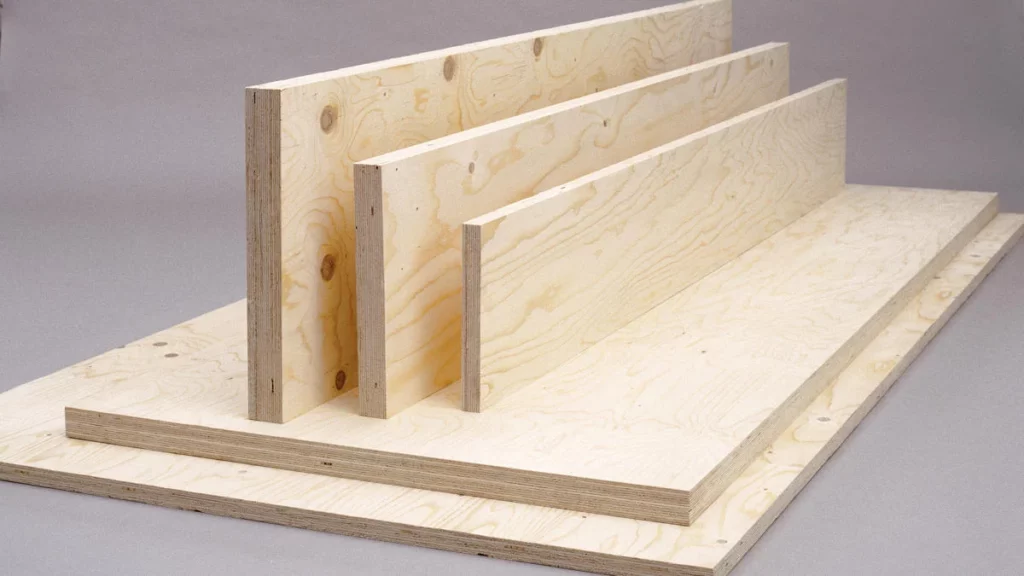

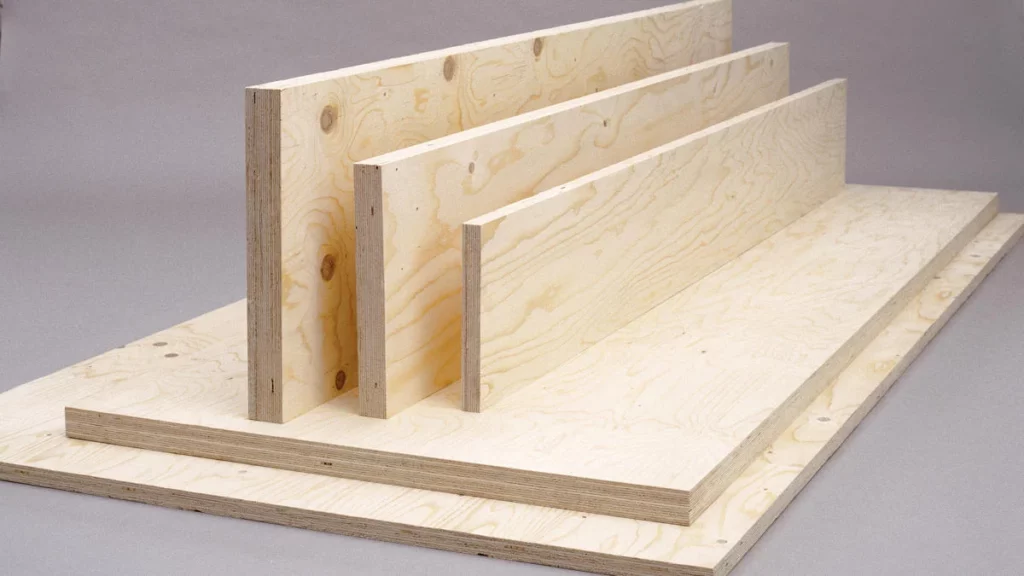

Before we dive into its advantages, it’s essential to understand what LVL formwork is and how it functions. LVL framwork is a type of engineered wood product constructed by bonding together layers of wood veneers with adhesive. This process gives LVL its exceptional strength and stability, making it an excellent choice for formwork in construction.

What is LVL Formwork?

LVL formwork is essentially a support system used in concrete construction. It is designed to mold and hold concrete in place while it cures, ensuring a solid structure. Unlike traditional timber formwork, LVL is manufactured under controlled conditions, which enhances its reliability and performance.

This form of construction material is often pre-fabricated, allowing for easy handling and installation. The uniformity of LVL ensures that it can withstand high loads, making it suitable for a wide range of applications, including bridges, high-rise buildings, and residential projects. Furthermore, LVL’s resistance to warping and twisting under stress means that it can maintain its shape and integrity even in challenging environmental conditions, which is a significant advantage over conventional timber options.

Learn about formwork plywood on: What Is Formwork Plywood and How Is It Used in Construction Projects

Key Components of LVL Formwork

The major components of LVL formwork include beams, panels, and supports. Each component is designed to work synergistically, creating a strong structure that can handle the stresses of pouring concrete.

- Beams: These are the primary supports that help distribute the load across the formwork system.

- Panels: Used to create the surface against which concrete is poured, panels can often be reused multiple times.

- Supports: Vertical elements that provide additional stability and are crucial for maintaining the integrity of the formwork during the pouring process.

In addition to these primary components, LVL formwork systems can also incorporate accessories such as bracing, ties, and clamps to enhance their stability and ease of assembly. Bracing helps to prevent lateral movement during the concrete pour, while ties ensure that the panels remain securely in place. This level of customization allows contractors to tailor the formwork system to the specific requirements of each project, optimizing both safety and efficiency during construction.

Moreover, the environmental benefits of LVL formwork cannot be overlooked. As an engineered wood product, LVL is often sourced from sustainably managed forests, making it a more eco-friendly option compared to traditional concrete formwork systems. The production process of LVL also generates less waste, and its durability means that it can be reused multiple times, further reducing the environmental impact of construction activities. This combination of performance and sustainability makes LVL formwork an increasingly popular choice among modern builders and architects. Learn more about sustainability on https://www.snhu.edu/about-us/newsroom/stem/what-is-environmental-sustainability

The Superiority of LVL Formwork in Construction

LVL formwork stands out among other types of formwork for several compelling reasons. Its durability and versatility are key reasons that contractors and engineers prefer it for their projects.

Durability and Strength of LVL Formwork

One of the most significant advantages of LVL formwork is its durability. The engineered design means it can withstand considerable weight and pressure without warping or failing.

This strength extends the lifespan of the formwork, allowing contractors to reuse it multiple times, reducing waste and increasing cost-efficiency. Moreover, LVL does not absorb water in the same way that timber does, meaning it remains stable and unaffected by environmental conditions.

Additionally, LVL formwork is resistant to many of the issues that plague traditional timber, such as insect infestations and fungal decay. This resistance not only enhances longevity but also ensures that the formwork maintains its structural integrity throughout the construction process. As a result, project timelines can be adhered to more closely, as the risk of delays due to formwork failure is significantly minimized. To read more about integrity click here.

Versatility of LVL Formwork in Various Construction Scenarios

LVL formwork is incredibly versatile, making it suitable for numerous construction projects. Whether it’s for residential, commercial, or industrial applications, LVL formwork can adapt to different shapes and sizes, accommodating the specific needs of a project.

Its lightweight nature allows for easier transport and handling, while still providing the significant support required for large pours. This adaptability ensures that builders can implement LVL in various settings without compromising safety or integrity.

Furthermore, LVL formwork can be customized to meet specific design requirements, allowing for intricate architectural features that might be challenging to achieve with other materials. This flexibility not only enhances the aesthetic appeal of the final structure but also supports innovative construction techniques. As architects and engineers continue to push the boundaries of design, LVL formwork provides the necessary support to realize these ambitious visions, making it an invaluable asset in modern construction practices.

Cost-Effectiveness of LVL Formwork

In today’s economy, cost is always a critical factor in any construction project. LVL formwork not only meets the budgetary constraints but also provides significant long-term savings.

Initial Investment and Long-Term Savings

While the initial investment in LVL formwork may be higher than traditional materials, its longevity and reusability make it a more cost-effective solution over time. Projects using LVL often experience fewer delays and reduced labor costs due to easier handling and setup.

Once utilized, LVL panels and beams can be reused for multiple projects, leading to considerable savings on material costs in the long run.

Maintenance and Replacement Costs

Maintenance and replacement costs are significantly lower with LVL formwork. Unlike traditional timber, LVL does not require frequent repairs or replacement due to its engineered moisture resistance and robustness.

Ultimately, the overall lifecycle costs of LVL formwork tend to be much lower compared to other types, making it a wise investment for any construction firm looking to optimize their budgeting.

Environmental Impact of Using LVL Formwork

As sustainability becomes increasingly important in construction, LVL formwork shines as an environmentally friendly option. Its production process involves sustainable sourcing and efficient use of materials.

Sustainable Sourcing of LVL Formwork Materials

The wood used in LVL production is often sourced from sustainably managed forests. This practice not only supports reforestation efforts but also ensures minimal environmental impact during harvesting.

Additionally, the manufacturing process of LVL maximizes wood usage, minimizing waste and offering a more eco-friendly alternative to conventional timber formwork.

Waste Reduction and Recycling Opportunities

Another significant environmental benefit of using LVL formwork is its potential for recycling. At the end of its lifecycle, LVL can often be repurposed or recycled, contributing to waste reduction.

Construction companies focusing on sustainability will find that LVL aligns well with their goals, allowing them to execute projects with a lower carbon footprint.

Safety Considerations for LVL Formwork

Safety is paramount in any construction project. LVL formwork, with its engineered properties, enhances safety on the job site significantly.

Risk Management with LVL Formwork

Using LVL in formwork systems aids in risk management as it offers predictable performance under load. This consistency reduces the risk of structural failures during the concrete pouring phase, which is when most accidents happen.

Furthermore, the lightweight nature of LVL minimizes injury risks related to heavy lifting and handling, contributing to a safer working environment.

Safety Standards and Compliance

LVL formwork also adheres to stringent safety standards and regulations, ensuring that it meets or exceeds industry requirements. Compliance with these standards helps protect both workers and the integrity of the construction project.

Companies utilizing LVL formwork can be assured that they are following best practices with a material that prioritizes safety and reliability.

In conclusion, LVL formwork represents an excellent choice for construction professionals seeking durability, cost-effectiveness, environmental responsibility, and safety. By selecting LVL, you are not just investing in a product; you are investing in a smarter future for construction.